Transformer Lamination Core

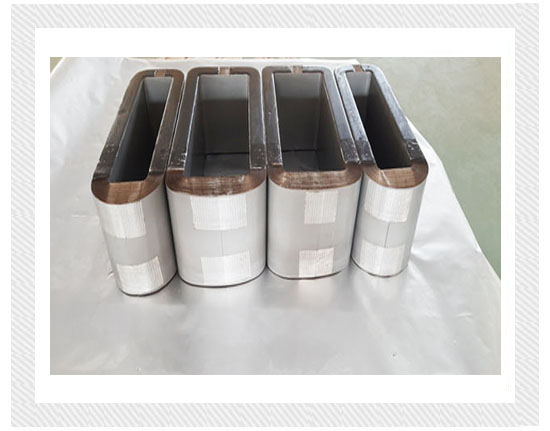

Transformer core lamination for power & distribution transformer is manufactured from various grades of cold rolled grain oriented steel. Lamination in various shapes & size are slit and cut to required accurate geometrical shapes with 90° & 45° angle cutting system. As manufacturing of transformer lamination involves a high degree of precision engineering, we always strive hard for crucial quality checks of burr level, stack height, dimension and required weight. We have firmly positioned ourselves as one of the prevailing CRGO Transformer Lamination Core Manufacturers and Suppliers, based in jaipur.We manufacture Transformer Core Laminations for Power and Distrubution Transformer. We are able to deliver CRGO Transformer Lamination Cores as leg or sheet packet, according to your packing requirements, inside of wooden box or on the pallets.

Basic process of the Product Manufacturing are :

Processing of Transformer lamination requires high degree of precision for which highly customized CNC machine are required. Our CNC Cut to Length machines are able to process lamination in various shapes and sizes with 90°/75°/45° angle cutting. The lamination can be cut to different dimension ranging from 25 mm to 1050 mm width and 100 mm to 5000 mm

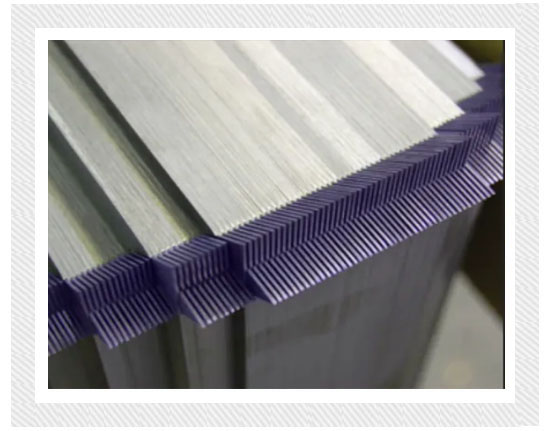

- Horizontal Step Lap design

- Vertical Step Lap design

- Conventional design

- Traction transformer core lamination’s

- Reactor core lamination’s

- Rectangular Freight loco lamination’s with multiple holes

- Rectangular P T Lamination’s

-

01 Specifications

. Transformer core lamination/cut to size lamination for the power and distribution transformers. Width up to 1000mm and length up to 5000 mm with auto stacking facility

. Strip lamination for instrument transformer industry

. Lamination processing capacity – 50,000 Metric Tonnes/annum -

02 Features

. Elegant Range of High durability

. Fine finish

. Smooth construction